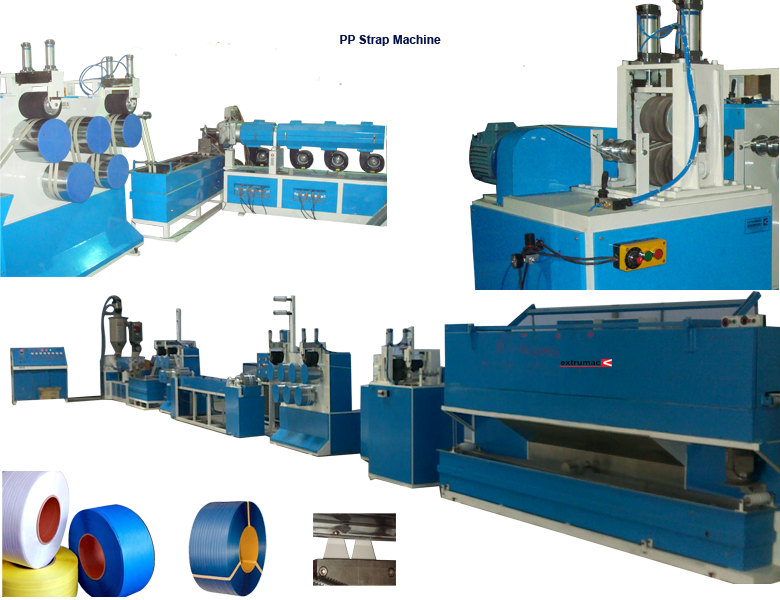

PP Strapping Band Manufacturing line produces high Productivity, best quality and cost saving. The stretched and embossed PP Band which will Be used effcrtively for manual packaging or mainly in automatic strapping machine for small and middle size cartons. this newly designed Machine provides faster production and superior product.

The Extruder adopts constant pitch type of screw for effective mixing of molten material.

The Extruder adopts constant pitch type of screw for effective mixing of molten material.

The Die having one or more channels as the Flat type.

The Die having one or more channels as the Flat type.

The stretching, Annealing and cooling units adopt three units of rollers for stepless adjustment of the stretching ratio and constriction ratio.

The stretching, Annealing and cooling units adopt three units of rollers for stepless adjustment of the stretching ratio and constriction ratio.

The embossing rollers are manufactured from Nitro alloy steel material vacuum heat treated for superior hardness and maximum wear resistance.

The embossing rollers are manufactured from Nitro alloy steel material vacuum heat treated for superior hardness and maximum wear resistance.

FEATURES

Maximum speed for each line 120 Mt/Min.

Maximum speed for each line 120 Mt/Min.

Strapping Band width 6, 9, 12, 16 and 19mm.

Strapping Band width 6, 9, 12, 16 and 19mm.

All chrome plated rollers for take-off for rust free operation.

All chrome plated rollers for take-off for rust free operation.

Extruding Output range 30 - 70 Kgs/Hr. in various size of Machine.

Extruding Output range 30 - 70 Kgs/Hr. in various size of Machine.

Nitro ally Barrel is Nitrogen treated, precision ground and stress relieved.

Nitro ally Barrel is Nitrogen treated, precision ground and stress relieved.

Provide Helical Gear Box in Extruder for high effciency and Energy saving.

Provide Helical Gear Box in Extruder for high effciency and Energy saving.

OPTIONAL EQUIPMENT

Screen Changer.

Screen Changer.

Chilling unit

Chilling unit

Groove feed screw for higher output.

Groove feed screw for higher output.

| SPECIFICATIONS |

| Model EXTMC | EXTMC 50BSPP | EXTMC 65BSPPSS |

| Screw dia (mm) | 50 | 65 |

| L/D Ratio | 28.1 | 28.1 |

| Max. Out Put (Kg./hr) | 32 | 50 |

| Max. Line Speed (Mtr./Min.) | 130 | 130 |

| Winder | 2 Station Winder | 3 Station Winder |

| Total Connected Load (KW.) | 40 | 60 |

| Plant Dimensions in Mtrs. (LXWXH) | 20 * 7 * 3.5 | 30 * 7 * 4 |